Modifying a KAFO Positive Cast

Modifying a KAFO Positive Cast

Once the positive cast has been made, it gets modified. Modifying the outline is the basis for an optimal fitting as well as a harmonious look of the resulting KAFO.

-

Producing the Work Basis

-

Fase 1/1

Create a positive cast. Stick the alignment aids through the already marked mechanical pivot points on the negative cast and fill the negative cast with plaster. Let the plaster harden.

Note: Check the heel height on the h-Cast.

-

Reinforcing the Foot Piece

-

Fase 1/2

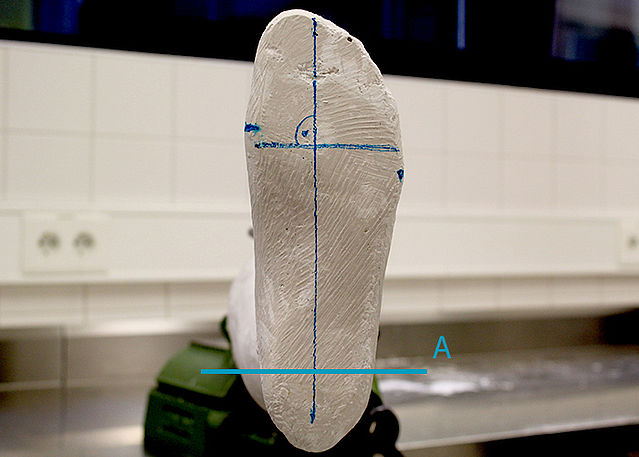

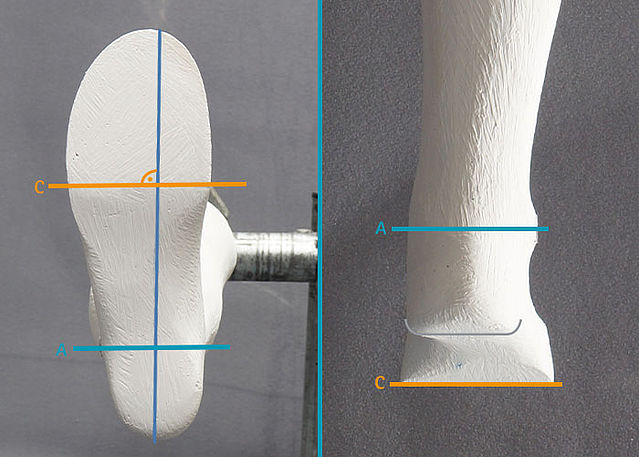

Mark the 1st and 5th metatarsal bone. Determine the rolling-off line between the two markings and draw it parallelly to the mechanical joint axes (auxiliary line A).

Fase 2/2

Place the positive cast with correct heel height on the h-Cast. Reinforce and prolong the foot area so that it provides more stability during later reinforcements.

-

Determining the Toe Spring

-

Fase 1/4

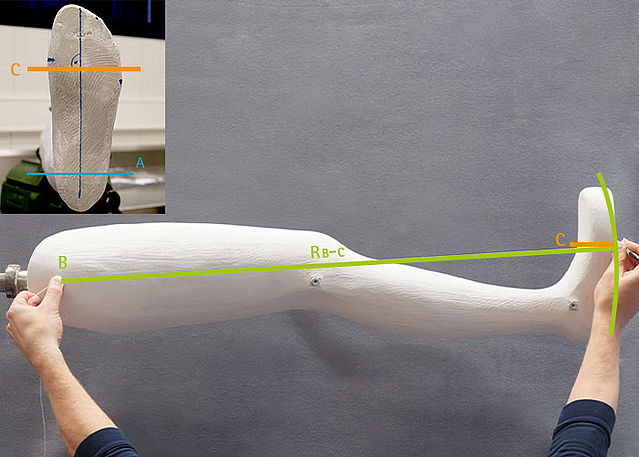

In order to define the toe spring, determine the trochanter (B) first. Tie a string to a pen. The string’s length (R) should match the distance from the trochanter (B) to the rolling-off line (C) (R B - C).

Hold the string at the trochanter (B) and place the pen at the rolling-off line (C). Use the pen to draw the circle line on the positive cast.Fase 2/4

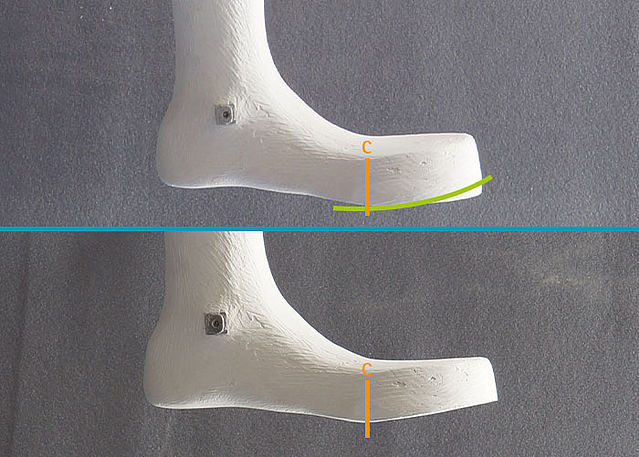

Modify the forefoot area of the foot piece corresponding to the drawn marking.

Note: Modify the bottom and the top of the foot piece parallel to one another. This way, the screw clamp can easily be attached in the later work steps.Fase 3/4

Mind the parallelism when modifying the foot piece. Modify the heel, the rolling-off area and the forefoot area parallel to the axis/axes.

Fase 4/4

Anatomically shaped positive cast.

-

Preparing the Trial Shell

-

Fase 1/3

Heat the trial shell material in an oven suited for plates (ca. 170°C/338°F) or an infrared oven (ca. 150°C/302°F). Wrap the heated plate around the positive cast and ensure a tight fit by vacuumising the plate. As soon as the material has cooled, saw out the trial shell and grind it.

Fase 2/3

Have the patient try on the trial shell. Make sure the trial shell fits well at the heel area so that you can check the length and volume as well as the joint's measurements and angles. Mark the areas which may need to be adjusted at the positive cast.

Note: When using a ventral shell, you should also saw out a ventral trial piece to check how it fits.Fase 3/3

Hold the lower leg in the trial shell and bring the leg into maximum extension to check if an extension beyond the position set by the KAFO is possible. This is especially important for the flawless functionality of automatic knee joint systems.

Note: Please make sure the patient does not sit on the trial shell!

-

Mounting the Assembly/Lamination Dummies

-

Fase 1/6

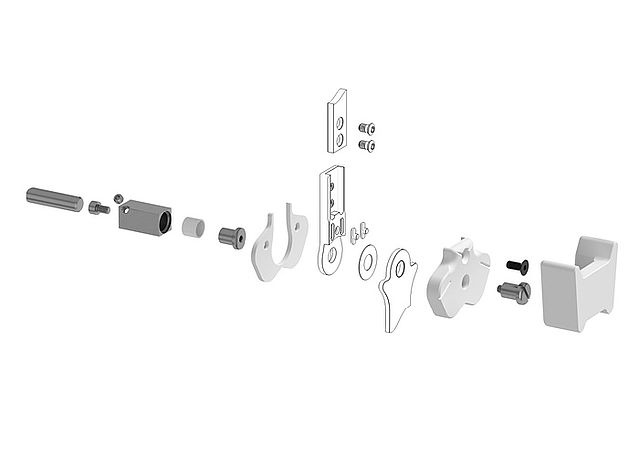

Mount the system joints to the holders in the positive cast in accordance to the exploded view drawing by using the assembly/lamination dummies.

Note: You can find exploded view drawings in our catalogue System Joints and Articulated System Side Bars.Fase 2/6

Take the middle of the lower leg as guidance and adjust the system case accordingly. Fix this alignment by connecting the joint retainer to the holder.

Fase 3/6

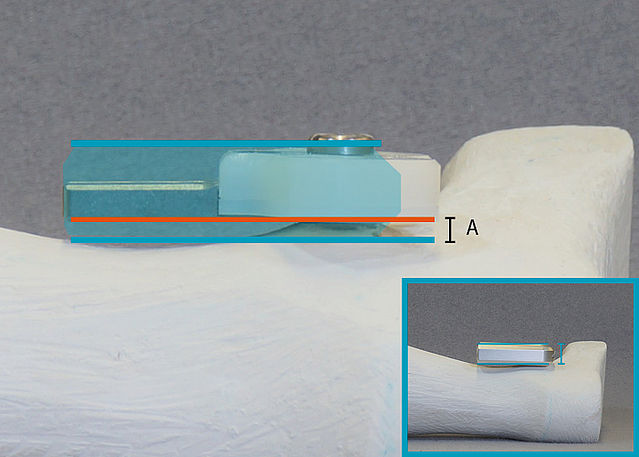

Note that the cover plate (blue) of the modular ankle joints is thicker than the mounted dummy. Leave enough space to the positive cast (A).

Fase 4/6

Optional Bilateral Construction with Round Material: Place the system knee joints. Leave some space to the positive cast for the dummy for the padding material and the laminate to fit in later.

Make a note of the medio-lateral measurement so that you can adjust the round material accordingly.Fase 5/6

Place the system joints with mounted holders into the positive cast and check the alignment.

At a bilateral construction without round material, check the ml measurement.

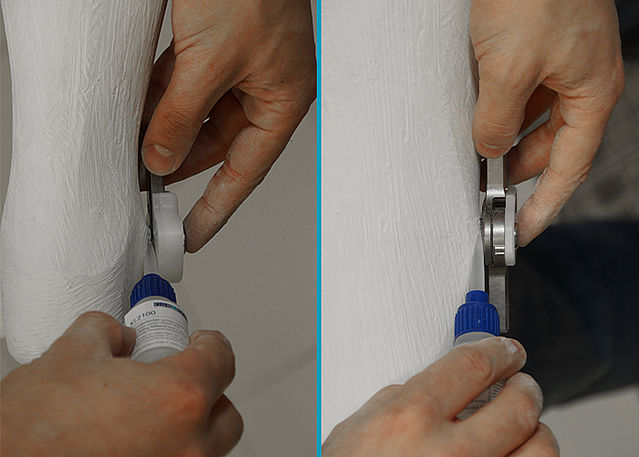

Secure the holders with fast-acting adhesive.

Note: Mind the safety data sheet when using fast-acting adhesive.Fase 6/6

For a unilaterally mounted system joint, fill the second hole (without holder) of the positive cast with plaster.

Note: Stuff the hole with paper before you fill it with plaster in order to be able to easily remove the holder of the system joint later on.

-

Designing the Orthosis’ Edges

-

Fase 1/5

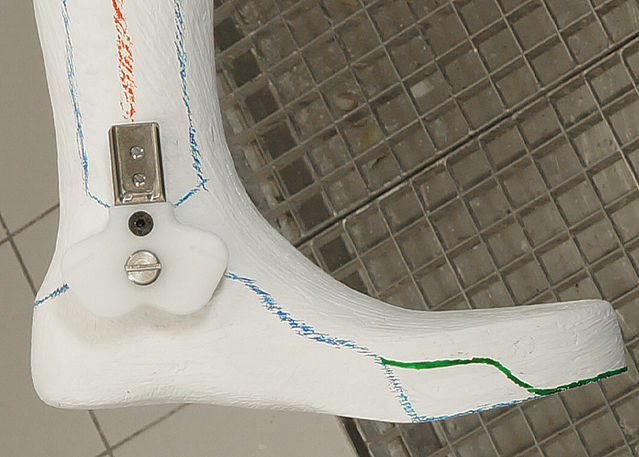

Mark the later course of the orthosis' edges along the foot piece on the positive cast. Use the blue line for a partially flexible foot piece and the green line for a rigid foot piece.

Fase 2/5

Mark the later course of the edges of the KAFO with partially flexible foot piece (blue lines) on the positive cast. Take into account the later course of the reinforced profile core (red lines).

Fase 3/5

Demount the system joints. Apply plaster around the holder to avoid sharp edges that could possibly damage the film tubes subsequently.

Fase 4/5

Pull a PA reinforcement stocking over the positive cast. It should fit tightly. Using hot-melt adhesive, stick cords of natural fibre (approx. 6–8mm diameter) along the marked edges of the PA reinforcement stocking.

Fase 5/5

Finished positive cast

View: lateral, anterior, medial, posterior

-

Applying the Padding Material Dummy

-

Fase 1/3

Heat the dummy for the padding material to 130°C and pull it over the positive cast. Cut the dummy for the padding material and remove it from the positive cast (afterwards). Grind the dummy for the padding material. Then, fix it on the positive cast by using a stapler.

Note: Use a material with a proper shore hardness so that the orthosis fits well and not too tightly on the leg later on.Fase 2/3

Detailed view: joint retainer in the positive cast

Fase 3/3

Finished positive cast with dummy for the padding material

-

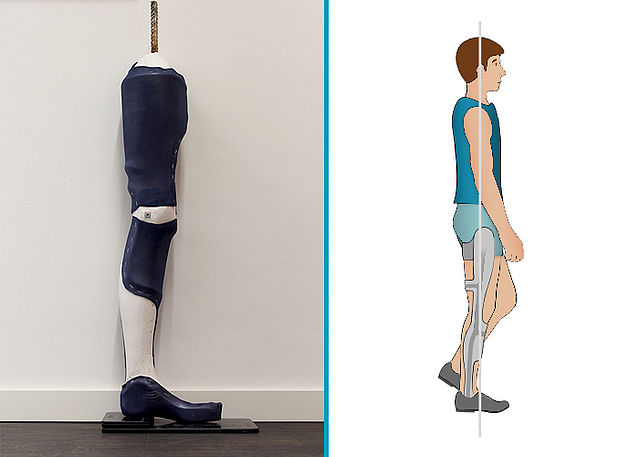

Alignment of the Orthosis

-

Fase 1/1

The alignment of the orthosis is based on the individual, gait-related normal posture of the patient. In mid stance, this results in a gait pattern that is as physiological as possible.

Last Update: 7 September 2022