Partially Flexible Foot Piece

Partially Flexible Foot Piece

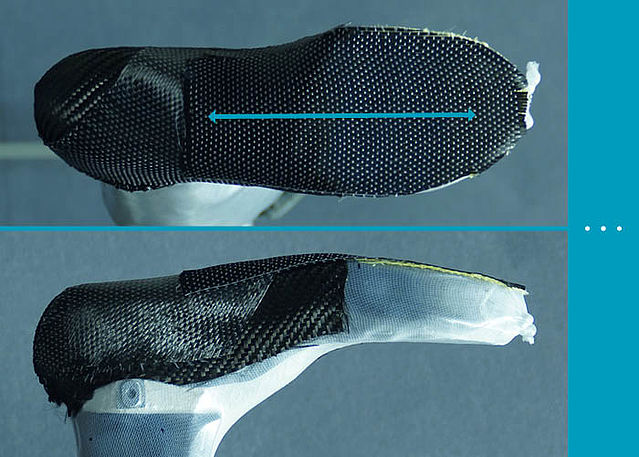

This online tutorial describes the production of a partially flexible foot piece. The partially flexible foot piece runs from the heel to the tiptoes. The area from the heel to the metatarsophalangeal joints is produced rigidly, meaning stiff. The area from the metatarsophalangeal joints to the tiptoes is produced flexibly.

Use the Orthosis Configurator to choose a foot piece. You will receive a recommendation for the production of a foot piece based on the patient data.

Click here to go to the online tutorial for producing a rigid foot piece.

-

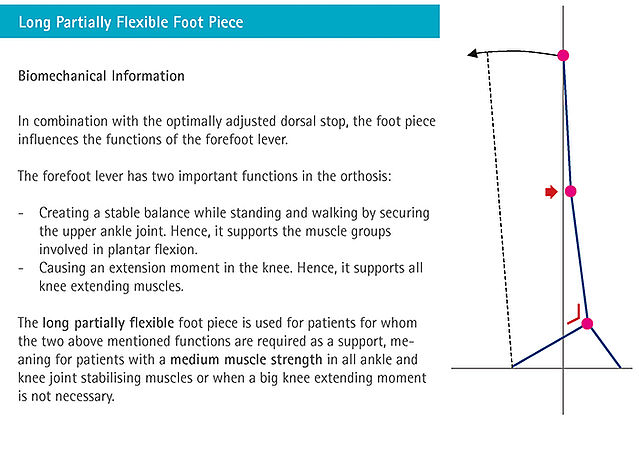

Biomechanical Basics

-

Fase 1/1

-

Reinforcing the Foot Piece

-

Fase 1/17

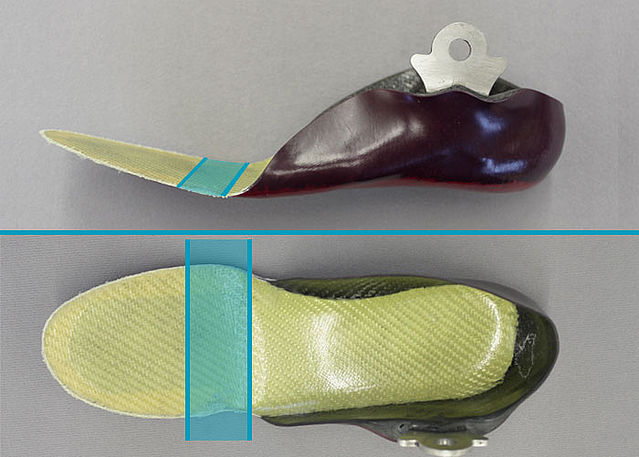

In order to increase the load capacity and useful life of the material of a partially flexible foot piece, reinforce the forefoot and rolling-off area (blue section) flexible and without a brim.

Note: A toes bank, or similar, can be attached subsequently if required.Fase 2/17

Please note! Due to the materials’ characteristics, always wear nitrile gloves while working with carbon or aramid fibre fabric.

We recommend using electrical scissors (e.g. Easy Cutter) to cut the separate fabric layers (carbon as well as aramid).

Note: Use adhesive transfer tape without backing material to secure the cutting edges. This way, the edges will not fray.Fase 3/17

Dry the aramid fibre fabric at 120°C in an oven for at least one hour. This way, you remove any moisture that has been absorbed during storage and improve the fabric’s properties for further processing.

Fase 4/17

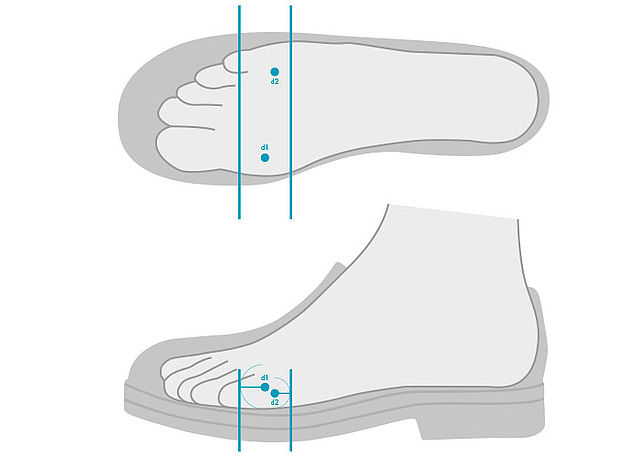

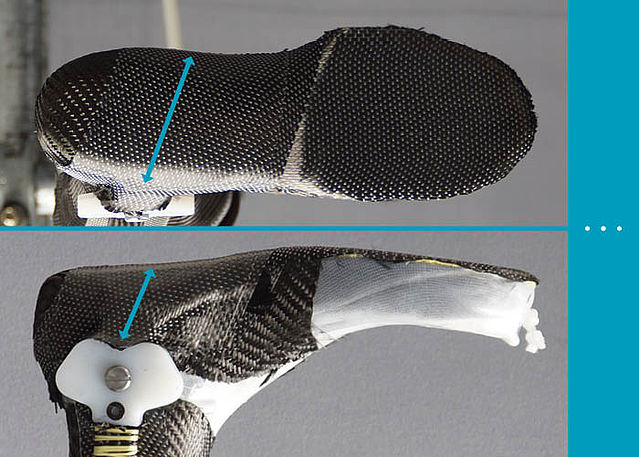

Consider the foot’s rolling-off area when laminating a partially flexible foot piece. It encompasses the area from anterior of the metatarsophalangeal joint (d1) of the big toe to posterior of the metatarsophalangeal joint (d2) of the little toe.

Fase 5/17

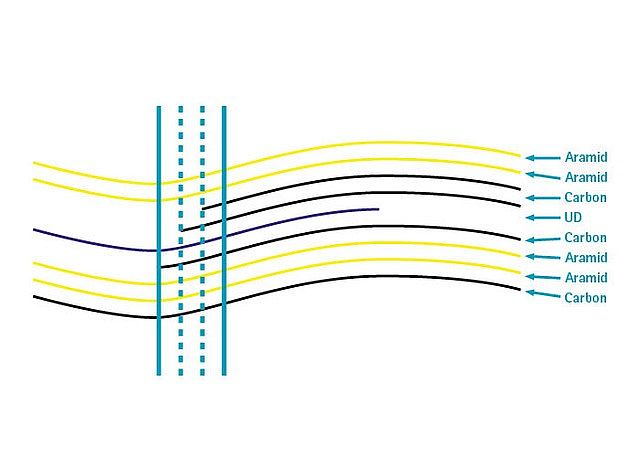

Consider the order of the different reinforcing layers when laminating a partially flexible foot piece. The quantity of the reinforcing layers should match the individual needs of your patient. The following reinforcing steps indicate where you can adhere more reinforcing layers, if necessary.

Note: Aramide is a flexible material that is particularly well suited for areas bearing dynamic loads.Fase 6/17

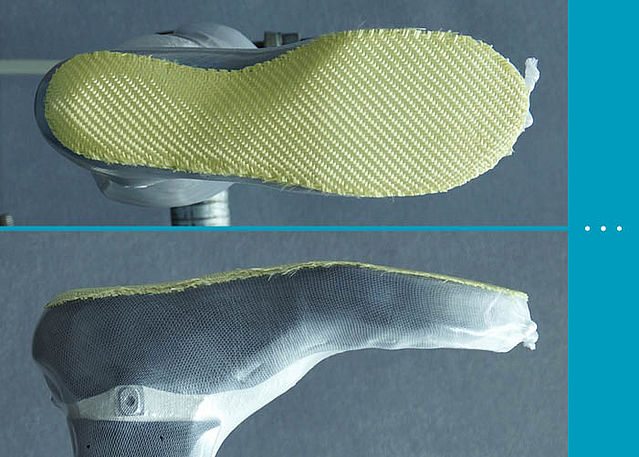

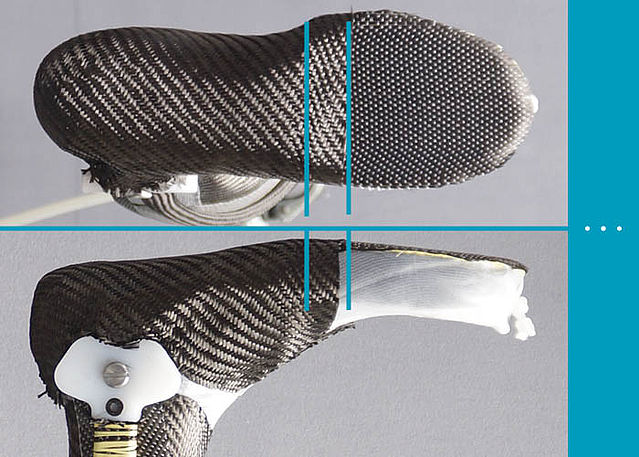

Scarcely cover an aramid fibre fabric pre-cut with adhesive spray and adhere it to the entire sole.

Use as many layers of aramid fibre fabric as you need (this is an exemplary picture).

Please note! Make sure to use the fibres stretched!Fase 7/17

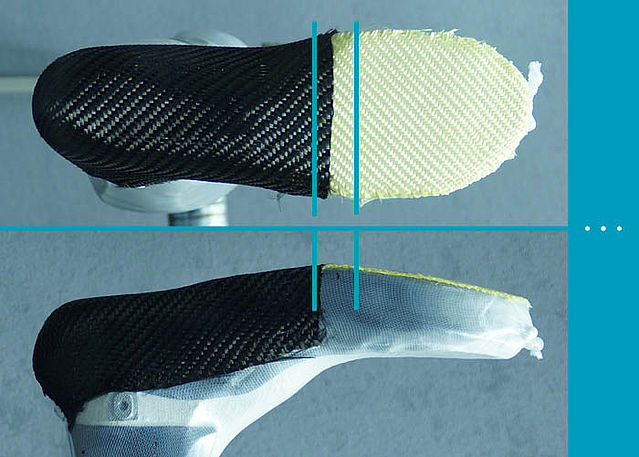

Scarcely cover a carbon fibre fabric pre-cut with adhesive spray and adhere it up to the rolling-off area. Then, cover the foot piece’s sole and sides with a carbon fibre fabric pre-cut.

Fase 8/17

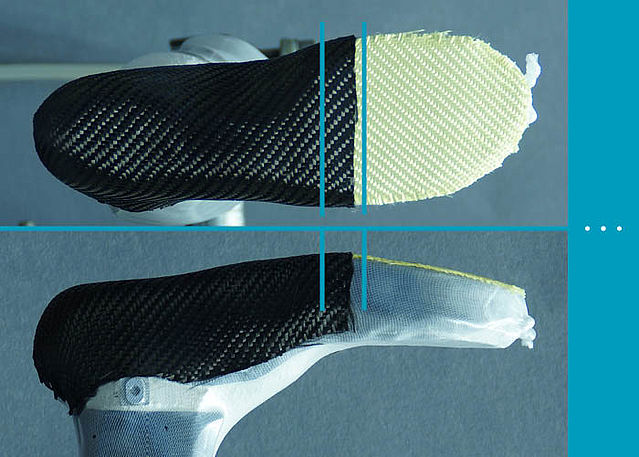

Keep on reinforcing with carbon fibre fabric. Each layer of the pre-cuts should end further ahead (distally) in the rolling-off area. Use as many layers of carbon fibre fabric as you need (this is an exemplary picture).

Note: Never spray the already adhered reinforcement, but only the pre-cut which still needs to be adhered.Fase 9/17

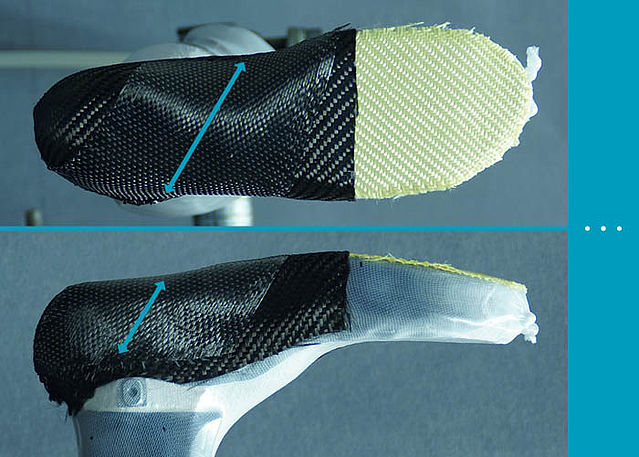

Diagonally reinforce from the joint to the toes with unidirectional carbon fibre band (10cm width). Mind the direction of the fibres (arrows).

Use as many layers of carbon fibre band as you need (this is an exemplary picture).Fase 10/17

Reinforce the forefoot area with unidirectional carbon fibre band (10cm width). Mind the direction of the fibres (arrows).

Use as many layers of carbon fibre band as you need (this is an exemplary picture).Fase 11/17

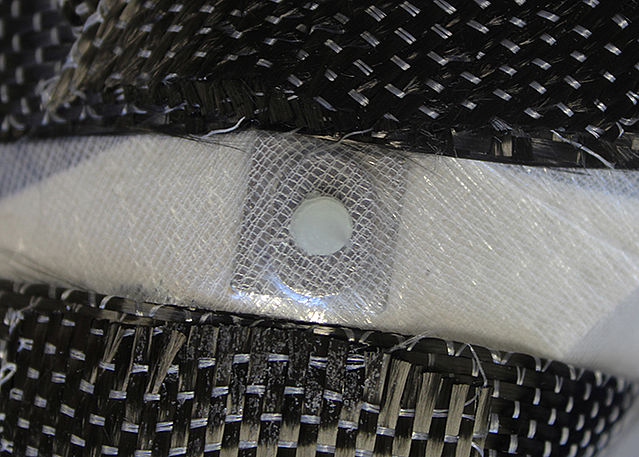

Apply some insulating wax to the thread of the joint retainer in order to seal it airtight.

Fase 12/17

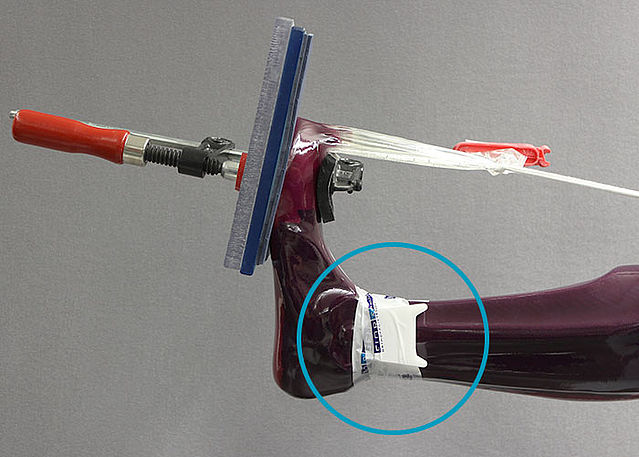

Mount the dummy with system string to the joint retainer. Find the correct position (the shape of the joint retainer matches the hollow for the bearing nut of the joint's upper part). Screw the retaining screw through the base film into the joint retainer and screw it tight.

Fase 13/17

Attach unidirectional carbon fibre band (10cm width) under the foot again. Mind the direction of the fibres (arrows).

Use as many layers of carbon fibre band as you need (this is an exemplary picture).Fase 14/17

Keep on reinforcing with carbon fibre fabric. Each layer of the pre-cuts should end further ahead (distally) in the rolling-off area.

Use as many layers of carbon fibre band as you need (this is an exemplary picture).Fase 15/17

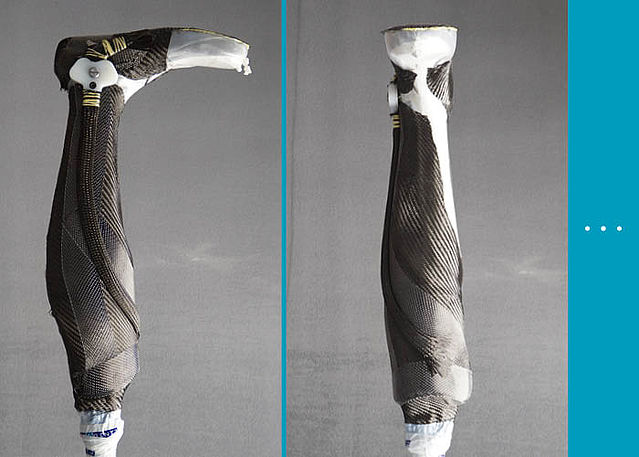

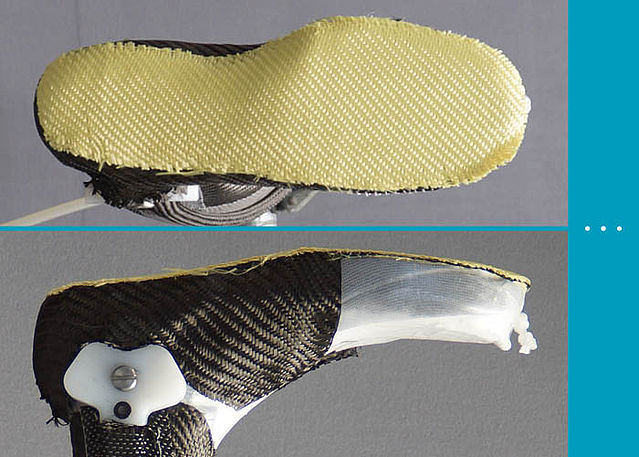

Finish reinforcing the partially flexible foot piece with aramid fibre fabric. While doing so, cover the entire sole.

Use as many layers of aramid fibre fabric as you need (this is an exemplary picture).Fase 16/17

Attach a final layer of carbon fibre fabric. Cover the dummy as well.

Fase 17/17

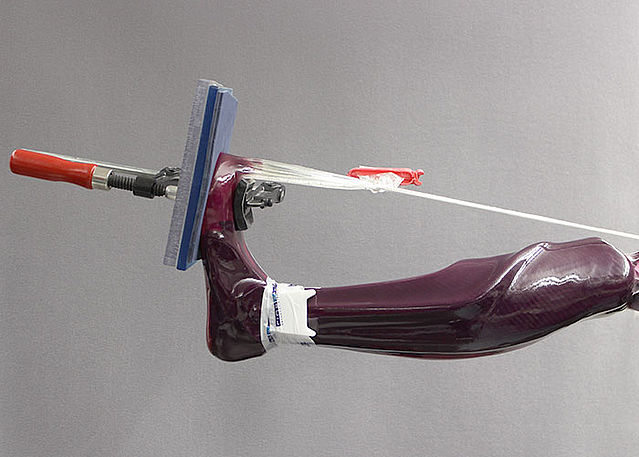

Finally, in order to fix the reinforcement layers, pull a decorative fabric or a PA reinforcement stocking (for a carbon look) over the model. Thus, the PVA film tube can easily be pulled over as top film layer.

Note: We recommend using a 0.10mm thick film layer.

-

Laminating the Foot Piece

-

Fase 1/5

This production technique is specifically adapted to our epoxy resin and hardener.

Please note! Follow the processing instructions and the safety data sheet for our epoxy resin and hardener. Precisely stick to the mixture ratio and thoroughly mix resin and hardener.Fase 2/5

Mix a sufficient amount of resin and hardener. Let the fabrics soak completely and rub surplus resin out.

Fase 3/5

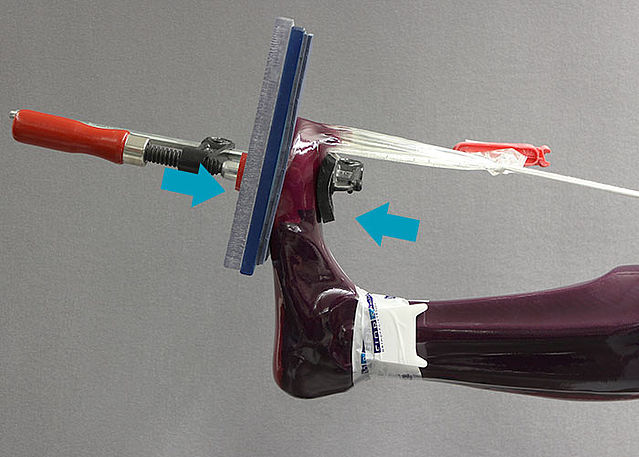

Press out the foot piece in order to receive the highest possible fibre volume ratio. While doing so, protect the film with some padding material and make sure to maintain the form of the modified toe spring.

Note: Use available shaping dummies.Fase 4/5

The shaping dummy increases the fibre volume ratio at the system joint area and facilitates mounting the NEURO SWING cover plate later. Align the shaping dummy, fitting the joint's upper part, and secure it with adhesive tape.

Fase 5/5

Let the model harden over night (at least 10 hours), under vacuum and at room temperature.

Please note! Also follow the processing instructions for epoxy resin.

-

Cutting the Foot Piece

-

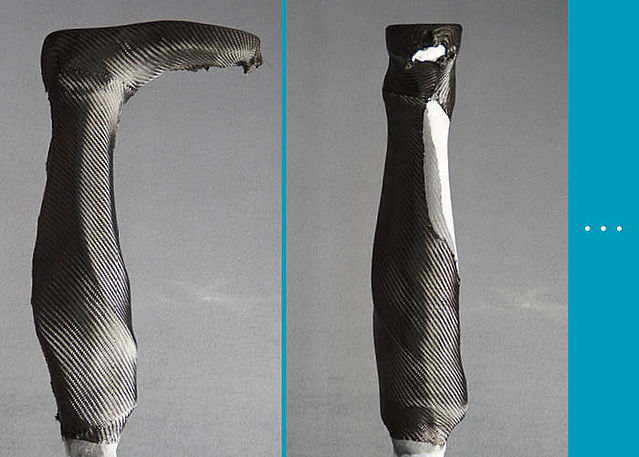

Fase 1/2

Use an oscillating saw to saw along the cutting edges in order to remove the orthosis parts from the model. You can see the recommended saw blade in the picture. Thus, you can saw very close to the system joint without damaging it.

Fase 2/2

Remove all laminate parts, which are no longer necessary. Then, you can remove the orthosis parts from the model.

-

Tempering and Grinding the Foot Piece

-

Fase 1/3

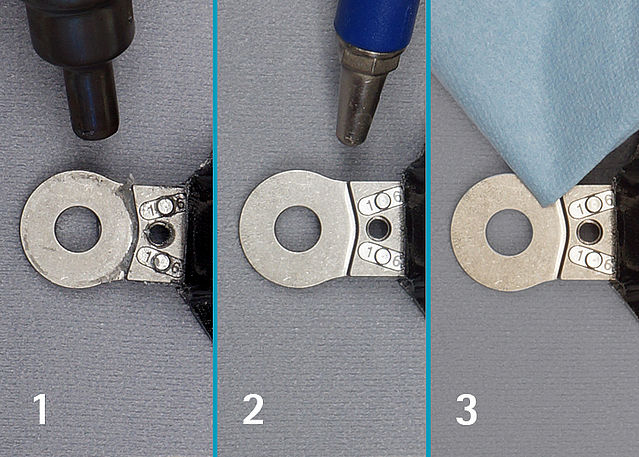

Clean all the joint areas as well as the system stirrup before you temper the parts of the orthosis. Heat all wax residues with a hot air blower (1) and blow the liquefied insulating wax out of the hollows (2). Remove all residues with a cloth (3). Remove the PVA film tube as well.

Fase 2/3

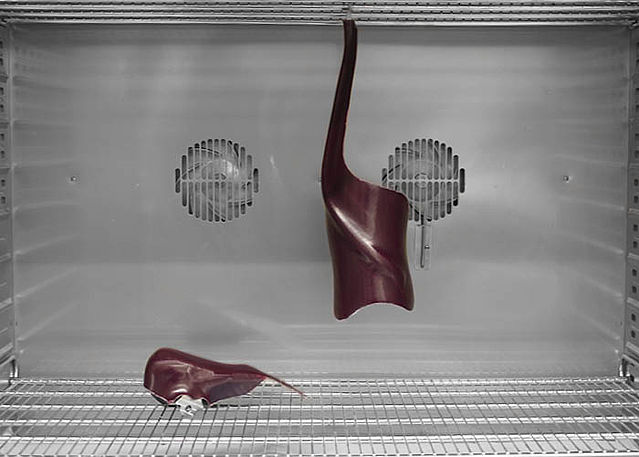

Temper all orthosis parts before grinding them. Place the orthosis parts into a cold convection oven and heat it up slowly. When tempered, the orthosis parts are stable and can be worked in the best possible way.

Please note! Also follow the processing instructions for epoxy resin.Fase 3/3

Grind the edges of the orthosis parts (e.g. with a belt grinder). However, it is essential to avoid predetermined breaking points in the metal! Also make sure that the flexible area of the foot piece is even (without brinks).

Note: Apply some insulating wax to the aramid fibre edges and subsequently grind them with coarse sandpaper.

Last Update: 24 June 2020